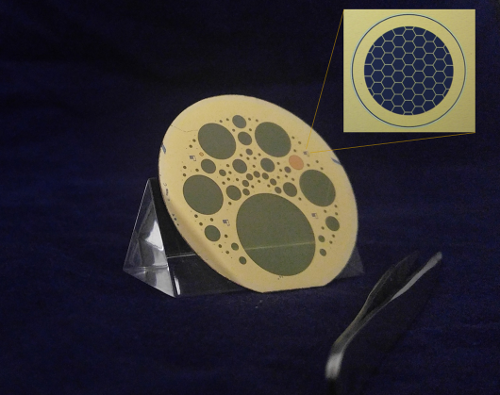

Device Design & Fabrication

Kyma is ready to team with you to bring your novel device ideas to life from concept, to layout, to reality.

Utilizing a wide range of design, simulation, and fabrication experience, Kyma can help with epi design, contact and dielectric schemes, as well as multi-level mask layouts. Kyma has access to a full suite of device processing facilities, supporting fabrication of all types of semiconductor devices including field effect transistors (FETs), Schottky barrier diodes, light emitting diodes (LEDs), and photoconductive semiconductor switches (PCSS). We can also validate your devices or films with routine Materials Characterization (XRD, AFM, XPS, SEM, etc) as well as electrical IV and CV measurements.

Routine processes available for wafers up to 150mm diameter include:

| Lithography (Optical & E-Beam): | Sub-Micron Features Supported |

| Metals via E-Beam Evaporation: | Ag, Al, Au, Co, Cr, Ge, Mo, Ni, Pd, Pt, & Ti |

| Metals via PVD Sputtering: | Al, Au, Co, Cr, Cu, Fe, ITO, Ni, Ta, Ti, TiW, TiO2, & W |

| Dielectrics via PECVD Deposition: | Nitride, Oxide, & OxyNitrides |

| Dielectrics via PE-ALD Deposition: | Al2O3, HfO2, ZrO2, HfZrO2, & TiN |

| Thermal Annealing: | N2, H2/N2, Air, & Vacuum |

| Etching (Wet & Dry): | ICP, RIE, & DRIE; Fluorine & Chlorine Chemistries |

If there are any additional processes you would like us to carry out for you just ask. Our network of partners enable Kyma to access most any type of well established semiconductor processing capabilities.

Recent testimonials about Kyma's device design & fabrication services appeared in both the FY16 Nevada National Security Site R&D Report and the FY17 Nevada National Security Site R&D Report.